High humidity and high salt environments in coastal areas are prone to cause metal rust. The following standards should be followed when selecting door and window anti-fall chains:

- Material priority level: 316 stainless steel > 304 stainless steel > copper (chrome-plated surface) > galvanized iron (not recommended). Among them, 316 stainless steel has the strongest salt spray corrosion resistance and is suitable for coastal areas.

- Surface treatment: Choose chains that have undergone passivation, nickel plating or chrome plating. The coating thickness must be ≥ 8 microns, which can effectively isolate water vapor and salt erosion; avoid iron or ordinary stainless steel (201 stainless steel) products without coating.

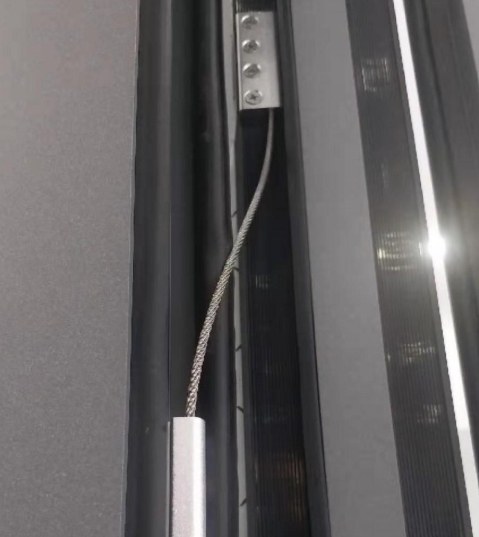

- Structural technology: Priority is given to one-piece chains (no welding points) or products with welding points treated with rust prevention to reduce rust risks; the chain connections should be smooth to avoid water accumulation.

- Load-bearing redundancy: The wind force in coastal areas is relatively large, and the material load-bearing should be 20% higher than that in ordinary areas (such as 50 kg for ordinary areas and more than 60 kg for coastal areas) to prevent failure to meet protection needs after strength reduction due to rust. After installation, it is recommended to check for rust every 2-3 months and maintain it in time.