The history of doors and windows is very long. Initially, they were made of wood and reinforced with iron sheets at each corner. In the early days, corner brackets were used. With the development of modern industry, aluminum alloy and plastic steel doors and windows emerged, giving rise to aluminum alloy corner brackets.

I remember when I was a child, every house had wooden doors and windows. By the time I was in high school, many households had already installed aluminum alloy doors and windows. Due to the poor thermal insulation performance of aluminum alloy doors and windows, people gradually began to pursue plastic steel doors and windows again. Plastic steel doors and windows also have their own problem, which is that the appearance is uniform and the color is mostly white

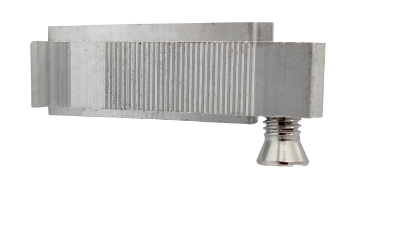

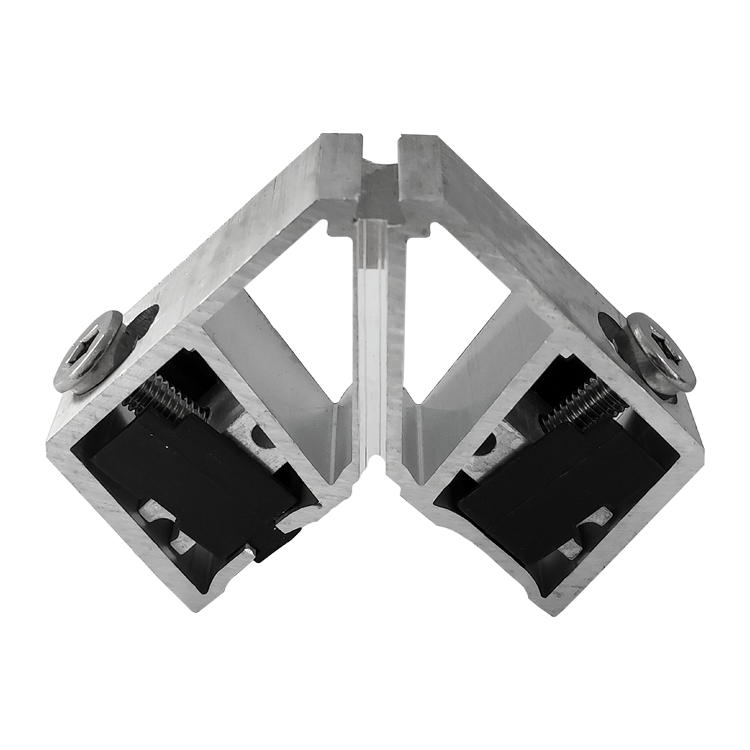

Finally, our key role - the broken bridge insulated doors and windows - emerged, which not only solves people's pursuit of beauty, but also has insulation performance requirements. At this point, the aluminum corner brackets for doors and windows come in handy. The connecting bracket of two aluminum profiles plays a crucial role in it.

Some friends have said that we can connect two aluminum materials directly without using corner codes, that is, to merge one aluminum material into the other. That's right, it's possible, but the maximum cost of a door or window is aluminum, and the cost of corner brackets is negligible in a door or window.

Is it just to save a few corner codes that greatly reduces the overall aesthetics of doors and windows? I think very few people would do this. In summary, it is undeniable that door and window corner codes make doors and windows look more beautiful overall.