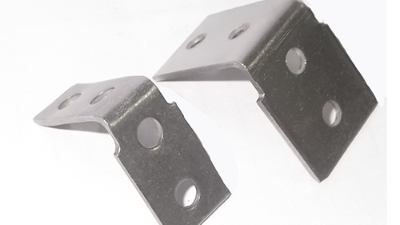

The curtain wall corner code is processed with standard angle steel, and the length can be customized according to the structure. If it is really special, steel plate bending processing can also be used, but the cost may be slightly higher. Galvanized corner brackets are used for bolted connections in curtain wall construction. There are two types of corner codes, one is steel corner code and the other is aluminum corner code. Steel angle brackets are used to directly connect the main keel to the structure, while aluminum angle brackets are used for inserting between the main and auxiliary keels on profiles.

The thickness of galvanizing varies depending on the application, and there are three standards for the thickness of the coating:

1: 0.1mm, used for ammonia synthesis equipment;

2: 0.02mm, used for water washing towers or cooling towers;

3: 0.01~0.03mm, used for metal components in the atmosphere, such as pole supports, bolts, cable conduits, instrument parts, etc.

Curtain wall corner code national standard: 200 * 200, 200 * 150, 200 * 250, 200 * 300, thickness 8mm~10mm.

National standard corner code: (50+50)*50*5、(100+100)*80*8、(60+70)*60*6。

The existing connection forms between the crossbeam and column of aluminum alloy curtain walls can be divided into the following types: Unit curtain walls generally have screw holes set in the cavity of the crossbeam, drill holes in the vertical frame, and connect them directly with screws. There are many connection forms for component curtain walls, and various connection forms for curtain walls at home and abroad have their own advantages and disadvantages.

Common structures include:

1. Horizontal and vertical plug-in type;

2. Corner code expansion floating type;

3. Corner code plug-in type;

4. Through slot bolt type;

5. Bidirectional locking type, etc.