The frame and sash assembly angle of doors and windows generally adopts a 45 ° butt joint assembly angle. The common connection methods for 45 ° angle connections include: movable angle code group angle, collision angle process group angle, injection glue group angle, etc. The injection glue group angle is further divided into pin injection glue group angle code and top wire injection glue group angle code.

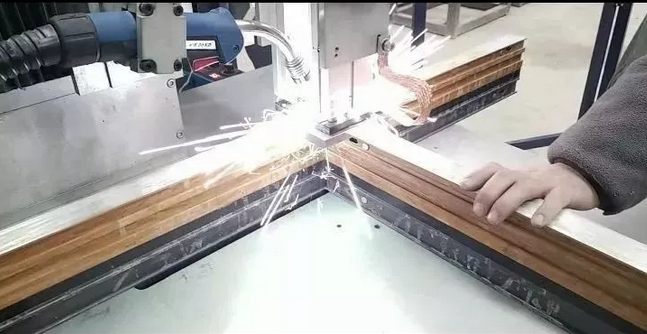

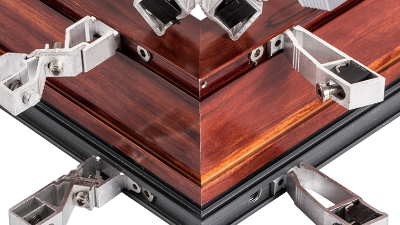

Seamless welding corner assembly is achieved by connecting two sections of 45 ° profiles through a seamless welding machine, polishing and removing the front weld bead, and then spraying the surface. Make the aluminum frame connection tightly sealed, difficult to distinguish with the naked eye, forming a unified whole, visually beautiful and unified.

Advantages of seamless welding corner assembly:

1) Seamless surface, good sealing performance, preventing corner leakage from occurring;

2) Overall beautiful appearance;

However, at the same time, seamless welding also has very obvious drawbacks:

1) Insufficient resistance to pressure

2) Over time, cracks are prone to occur, such as surface forming cracks, transverse cracks, solidification cracks, segregation cracks, cracks under the weld bead, weld bead cracks, etc. And the reasons for these are related to low melting point elements. Because it is seamlessly welded as a whole, once cracks appear, the entire window can only be replaced.

Angular strength is one of the most important performance indicators for evaluating the quality of doors and windows! The insufficient strength of the connection angles of the frame can lead to corner gaps and deformation of the connections, resulting in the loss of the basic frame retention ability of doors and windows, causing problems such as door and window leakage and inability to open normally, seriously affecting the sealing and use of doors and windows.