During the assembly process, a professional two-component glue gun is used for glue injection. The glue injection angle code two-component glue gun can meet the needs of various glue mixing, avoiding problems such as incorrect mixing ratios, uneven mixing, and high waste during use, greatly improving the efficiency and quality of glue application.

The function of corner codes is for decorative engineering and furniture assembly. As long as a 90 ° right angle needs to be fixed, corner codes will be used. Corner codes make furniture more three-dimensional. In the production of doors and windows, corner codes are used for connecting components such as door and window sashes and frames. In industrial development, the requirements for craftsmanship and quality are increasingly high, and appearance and practicality coexist. Aluminum alloy doors and windows have begun to have adhesive corner codes.

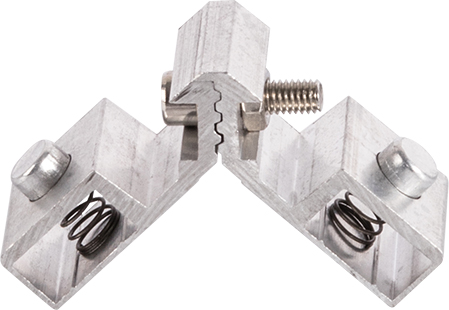

In the production of general aluminum alloy doors and windows, different types of door and window processes will use different corner codes. The characteristics of aluminum alloy corner brackets are material stability, strong weather resistance, resistance to deformation, and long service life. In terms of waterproofing and sound insulation, the aluminum alloy corner code is now divided into three types; 1. Activity corner code 2. Overall corner code 3. Glue corner code. Each type of corner code has different effects and advantages. The movable corner code is easy to install and debug, and can be disassembled and used multiple times. The impact corner code, also known as the integral corner code, is non removable, firmly connected, and has a compact structure with easy installation and better sealing.

In terms of material, there are two types of door and window corner codes, namely plastic corner codes and aluminum alloy corner codes.

The characteristics of adhesive corner codes are lightweight and affordable. Plastic itself has a certain degree of resilience, which can provide a certain buffering effect when opening and closing doors and windows significantly. Even though plastic corner codes have excellent shock absorption and noise reduction functions, their drawbacks are more obvious. Plastic corner codes have poor heat resistance and can deform at slightly higher temperatures. They are prone to combustion, and even thermosetting resins can smoke and easily peel off at temperatures exceeding 200 degrees Celsius.