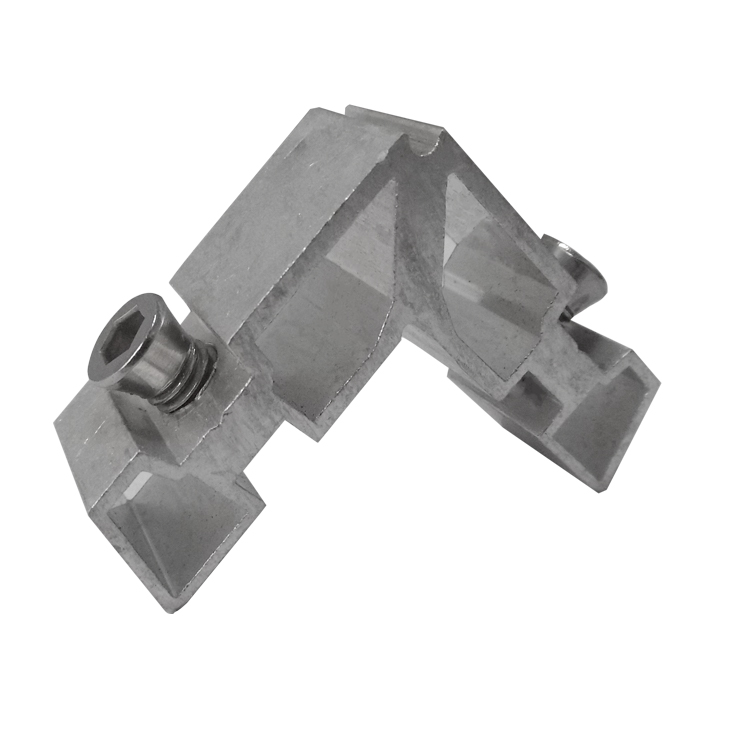

Use die cast impact angle injection corner codes. Unable to process on-site and requires precise 45 ° cutting of profiles.

Advantages: It can achieve seamless connection of profiles and is less prone to water ingress and cracking, with improved sealing and waterproof performance. It also has better sound insulation performance and is less likely to loosen when impacted by injection molding technology. Suitable for areas with frequent typhoons.

Unable to process on-site, the cost of die-casting formed corner codes is expensive.

Pin injection process: Generally, a Class A material integral corner code is used without a locator, which is fastened and positioned by two pins. At the same time, a more weather resistant corner glue is used for injection, and the glue is filled into the corner code through the internal guide groove to make the corner tighter. Pin is actually a combination and upgraded body of locator and screw, with stronger stability performance.

Advantages of adhesive corner code: It has stronger toughness and stability. At the same time, it also has stronger sealing and waterproof properties, and better sound insulation performance. Suitable for areas with frequent typhoons.