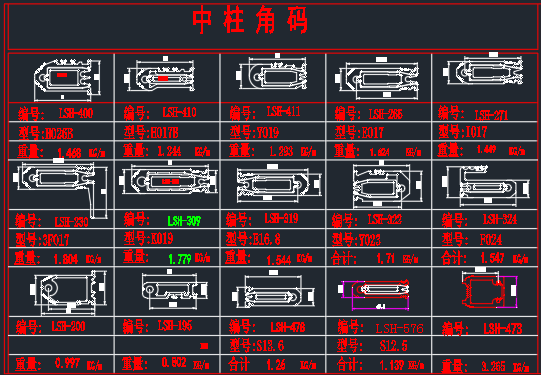

Product Introduction:

Expansion glue injection corner bracket for mullion is another important connection component in the manufacturing of doors and windows. The design principle mainly realizes the fastening and reinforcement of the profile through the principle of mechanical expansion, which is different from glue injection angle corner. With its unique physical fixing method and adaptability, the expansion angle corner occupies an important position in the door and window industry, especially for scenes with high requirements for installation efficiency, vibration resistance and cost control. The core features of this type of bracket will be analyzed from technical performance, application advantages and applicable scenarios as following:

1. Mechanical expansion fixing principle: The core of the expansion angle bracket lies in its physical expansion structure, which is usually made of high-strength stainless steel or aluminum alloy, with built-in expansion bolts or expansion blocks. Dynamic occlude force: During installation, the internal expansion structure of the angle bracket expands outward by tightening the screws and forming a tight mechanical occlude with the profile cavity, and the contact area can reach more than twice of the traditional angle bracket.

2. High vibration and fatigue resistance

Anti-loosening ability: The expansion structure can maintain stable occlude in a vibrating environment. Laboratory tests show that connection strength only decreases by 5%-8% after 100,000 high-frequency vibrations, which is much better than ordinary angle brackets.

Resistance to repeated loads: Suitable for doors and windows which are frequently opened and closed (such as entrance doors of commercial buildings), the metal fatigue threshold of the expansion angle bracket is higher and not easy to deform after using for a long-term.

3. Convenient installation and adjustability

Ready to use: No waiting time for glue injection. During installation, only screws tightening is required for fastening, which improves construction efficiency by more than 40%, and especially suitable for projects with tight construction schedules.

Fine-tunable design: Some expansion angle brackets are reusable after installation, reducing dependence on profile cutting accuracy and reducing installation errors.

4. Environmental adaptability and durability

Extreme temperature Resistance: The metal expansion structure has stable performance in the range of -50℃ to 150℃ without colloid cracking or shrinkage problems, and is suitable for extremely cold areas or glass curtain walls exposed to direct sunlight.

Anti-corrosion: Adopting surface anodizing or plating process (such as Dacromet coating), and salt spray resistance test exceeds 1000 hours, which is suitable for corrosive environments such as coastal areas and chemical plants.

5. Cost advantage and convenient maintenance

Easy maintenance and replacement: the expansion angle bracket can be taken out and reused without loss if disassembly and maintenance required, which avoid the destructive removal of the injection angle bracket due to solidification of colloid.