The service life of injection - glued corner connectors is affected by various factors. Under normal usage conditions, it generally ranges from 15 to 30 years. The following is a specific analysis:

Material quality: High - quality injection - glued corner connectors usually use high - strength aluminum alloy or stainless - steel materials, which have good corrosion resistance and mechanical strength. If the material quality of the corner connector itself is poor, problems such as deformation and rusting may easily occur during use, thus shortening the service life.

Performance of the glue: The performance of the corner - joining glue used in injection - glued corner connectors is of crucial importance. High - quality corner - joining glue has excellent bonding strength, weather resistance, and anti - aging properties, enabling it to maintain a firm connection between the corner connector and the profile during long - term use. Generally, high - quality corner - joining glue can maintain good performance for more than 15 years in outdoor environments after rigorous aging tests, thus ensuring the overall service life of the injection - glued corner connector. However, inferior glue may experience phenomena such as aging and cracking within a few years, resulting in loose connections of the corner connectors.

Usage environment: If the doors and windows are in a harsh environment, such as long - term exposure to high - temperature, high - humidity, strong - acid or strong - alkali corrosive environments, the service life of the injection - glued corner connectors will be affected. For example, for doors and windows in coastal areas, due to the high salt content in the air, there is a strong corrosive effect on metal corner connectors, accelerating the corrosion rate of the corner connectors. At the same time, it may also affect the bonding performance of the glue, shortening the service life of the injection - glued corner connectors. Conversely, in a dry and well - ventilated indoor environment, the service life of the injection - glued corner connectors will be relatively long.

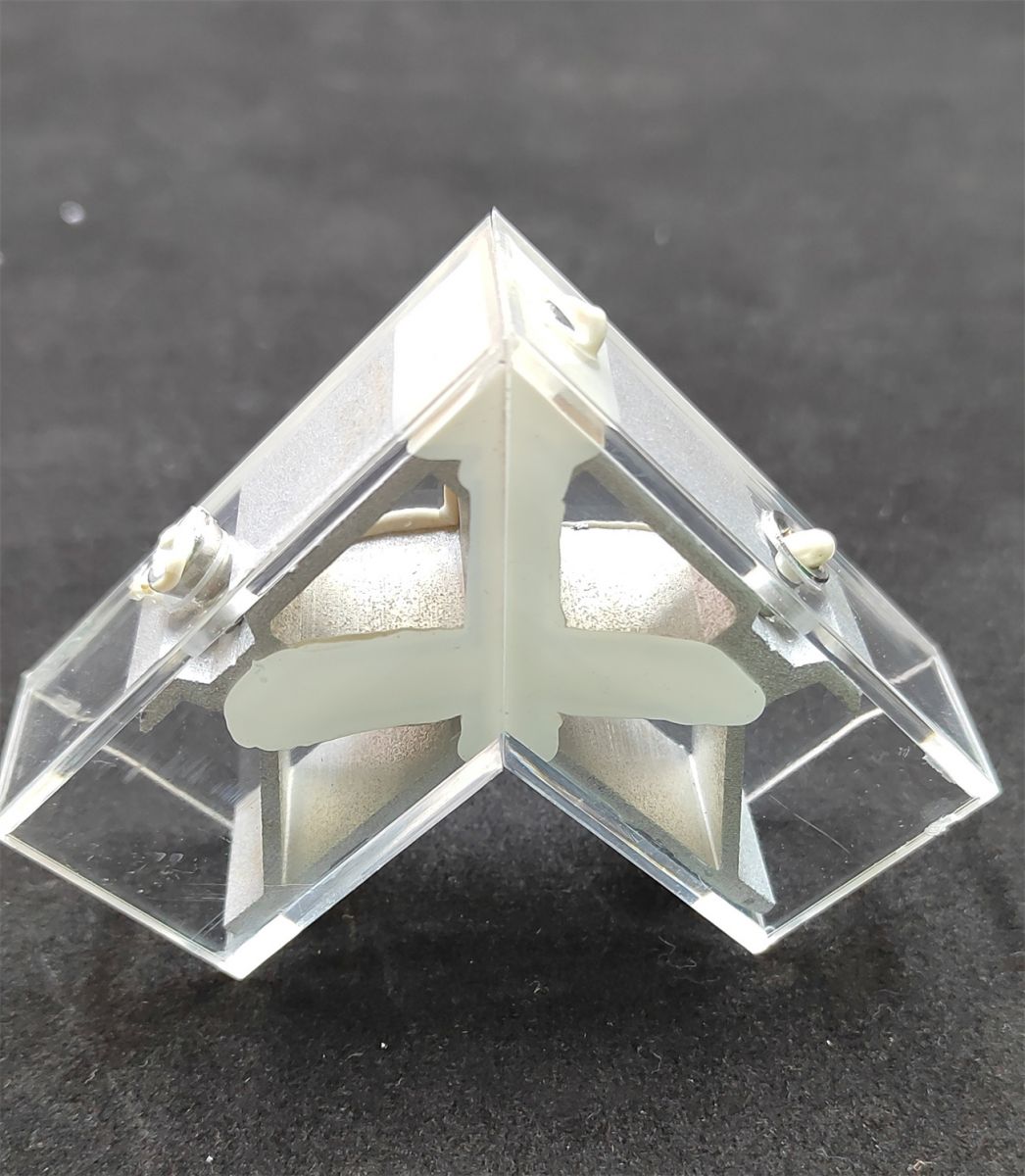

Installation quality: Correct installation is the key to ensuring the service life of injection - glued corner connectors. If the gap between the corner connector and the profile is too large or too small during installation, the glue is unevenly filled, or the screws are not firmly fixed, etc., it will affect the performance and service life of the corner connector. For instance, if the gap is too large, the glue cannot be effectively filled, and the connection between the corner connector and the profile will be loose. It is likely to become loose during the use of the doors and windows, thus affecting the service life.

If the corner connectors are regularly inspected and maintained during use, and problems that occur to the corner connectors are promptly discovered and addressed, such as cleaning surface dirt and replacing aging rubber strips, etc., the service life can be extended to a certain extent.

END