The service life of the "solar panel quick fastening clip middle clamp" is affected by multiple factors such as material quality, environmental conditions, and installation and maintenance, resulting in significant differences.

I. Core influencing factors and life performance

1. Environmental corrosion intensity

Dry and clean environment: In deserts and plateaus, the service life of aluminum alloy fixtures can reach 10 - 15 years, and stainless - steel fixtures are almost non - corrosive with a service life of over 20 years.

Moderate corrosion environment: In suburban areas of cities and non - coastal rooftops, the anodized aluminum alloy has a service life of about 10 years, and 304 stainless steel can reach more than 15 years.

High - corrosion environment: Ordinary aluminum alloys within 1 km of the coast or around chemical plants may rust and fail in 5 - 8 years. It is necessary to compulsorily use 316 stainless steel or titanium alloy fixtures (with a service life of 25 years +).

2. Installation and maintenance quality

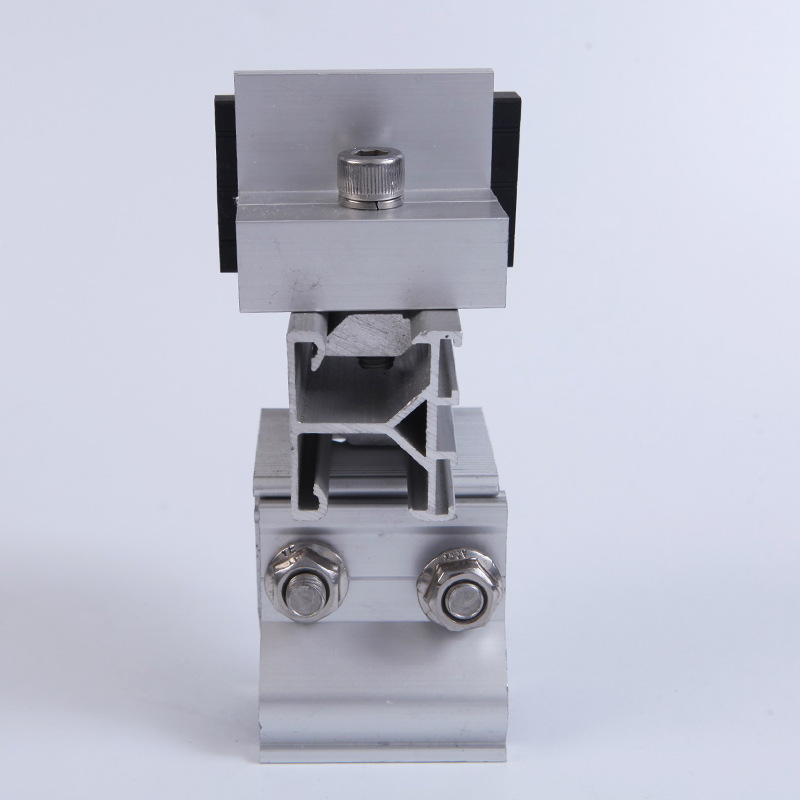

Correct installation: The bolt torque of the solar panel quick fastening clip middle clamp meets the standard, and the component frame is clean without debris, which can avoid early fracture caused by stress concentration.

Regular maintenance: Check the loosening of fixture screws and the aging of rubber pads (such as cracking and hardening) every 2 - 3 years. Timely replacement can extend the service life by 3 - 5 years.

Wrong operation: Over - tightening the screws causing the clamp block to deform or using non - matching fixtures (such as mixing different materials) may shorten the service life by more than 50%.

II. Practical suggestions for extending service life

1. Material selection optimization

Give priority to 316 stainless - steel fixtures or high - grade aluminum alloy + double - layer anodization, especially in high - corrosion areas.

Avoid contact between different metals (such as an aluminum alloy fixture with a steel bracket), g and add insulatingaskets to prevent electrochemical corrosion.

2. Installation detail control

Apply butyl rubber strips at the contact points between the "solar panel quick fastening clip middle clamp" and the component frame to prevent rainwater from seeping into the gaps and causing corrosion of the gaps. For bolt connections, use locknuts (such as nylon locknuts) or spring washers to reduce loosening caused by long-term vibration.

3. Regular maintenance measures

Annual inspection: Visually inspect whether there are rust marks or cracks on the surface of the solar panel quick fastening clip middle clamp, and check if the rubber pad is aged (if it is hardened and cracked, it needs to be replaced in a timely manner).

Every 5 - year inspection: Randomly select 5% of the solar panel quick fastening clip middle clamps for torque testing and clamping force measurement.

Inspection after extreme weather: After typhoons and heavy rains, focus on checking the displacement of fixtures and the loosening of bolts, and reinstall or replace them in time.

III. Treatment plans after the service life expires

1. Overall replacement

When more than 20% of the fixtures show severe corrosion or failure, it is recommended to replace all with higher - specification products.

2. Local replacement

When individual fixtures are damaged, products of the same model as the original should be selected to avoid mixing different batches or materials of fixtures.

3. Scrap recycling

Aluminum alloy fixtures can be returned to the steel mill for recycling, and stainless - steel fixtures can be refined for metals by professional companies to reduce environmental pollution.

END