The solar panel quick fastening clip middle clamp has significant advantages in the installation of photovoltaic systems. Its design focuses on core requirements such as efficient installation, stable fixation, and environmental adaptation. The following is an analysis of the specific advantages:

I. High installation efficiency: Quick positioning and tool - free operation

1.Tool - free and quick installation

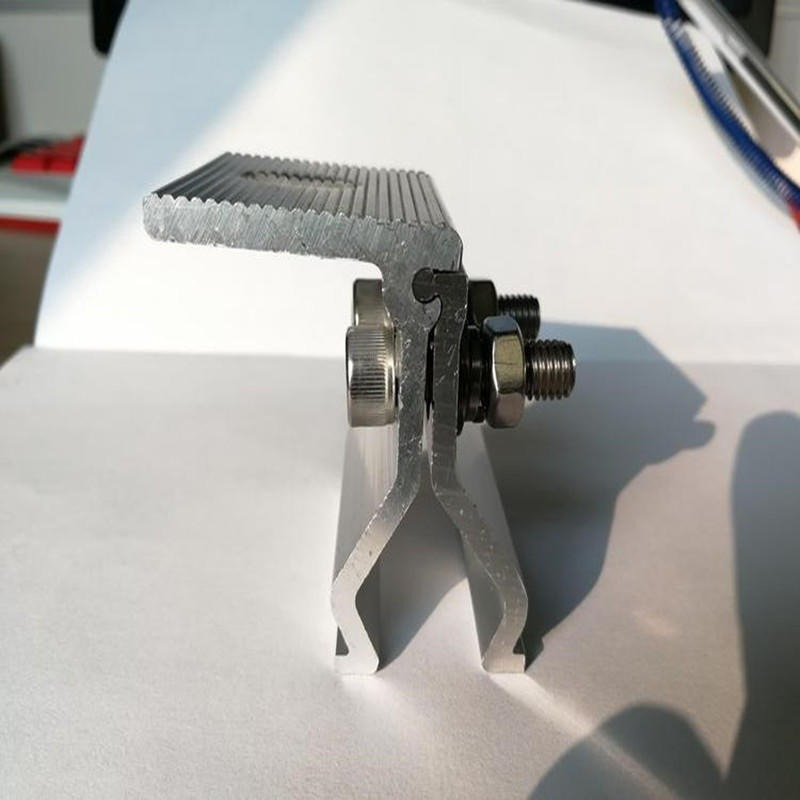

Some of the solar panel quick fastening clips middle clamps adopt spring buckles or elastic structures. No tools such as screwdrivers or wrenches are required. Fixing can be completed by directly pressing or snapping into the track and the battery panel frame, which greatly shortens the installation time.

Example: The solar panel quick fastening clip middle clamp can slide freely within the track through the "intelligent patented nut". There is no need for pre - drilling or positioning during installation, and it can be adjusted directly according to the position of the solar panel.

2.Flexibly adjustable positioning design

The solar panel quick fastening clip can middle clamp slide freely horizontally along the track, adapting to different panel spacings or array layouts (such as horizontal series connection, vertical parallel connection), and is especially suitable for on - site error adjustment (such as bracket installation deviation).

II. Superior mechanical properties: Stable clamping and load - bearing capacity

1.Reliable mechanical clamping force

The top clamping part or side clamping blocks are in close contact with the panel frame, and the friction force is used to resist horizontal wind loads and vibration loads. For example, the clamping force of an aluminum alloy clamp can reach several hundred Newtons, ensuring that the solar panel does not loosen in strong winds (such as typhoons above level 10). When used in conjunction with edge clamps (end clamps), multi - point balanced stress can be formed to disperse the overall stress of the solar panel, avoiding local deformation or cracking of the frame.

2.Fatigue - resistant and vibration - resistant design

Fasteners (such as stainless - steel bolts and spring washers) adopt anti - loosening structures and are not easy to loosen due to vibration during long - term use. Some high - end clamps are internally equipped with elastic buffer pads to absorb environmental vibration energy and reduce component wear.

III. Strong environmental adaptability: Weather resistance and compatibility

1.Corrosion - resistant materials ensure long - term use

The main body is made of aluminum alloy 6005 - T5 (with surface oxidation treatment), and the fasteners are made of stainless steel 304/316, which can withstand harsh outdoor environments such as high humidity, salt spray, and ultraviolet rays, and the service life can reach more than 25 years (matching the service life of photovoltaic modules). Example: In coastal areas or industrial pollution areas, the use of stainless - steel clamps can effectively prevent structural failure caused by corrosion.

2.Compatible with a variety of panel and bracket specifications

It is suitable for common frame thicknesses such as 30mm, 35mm, and 40mm. Some models support frameless components or special profiles (such as trapezoidal frames). It can be compatible with different types of tracks (such as C - shaped tracks, U - shaped tracks, and T - shaped tracks), and can achieve “one - clip - multi - use” by replacing sliders or bases, reducing the project procurement cost.

IIII. Cost advantages: Lightweight and low - maintenance

1.Lightweight design reduces load

The weight of an aluminum alloy clamp is only 1/3 - 1/2 of that of a steel clamp, reducing the load - bearing pressure on the roof or bracket. It is especially suitable for old buildings or flexible bracket scenarios, avoiding the cost of additional structural reinforcement.

2.Maintenance - free or low - maintenance

The structure is simple and compact, with no easily damaged moving parts (such as rubber seals), and no regular maintenance is required during long - term use. Compared with traditional welding or riveting fixation methods, it can save later maintenance man - hours and costs.

END