With the rapid development of the construction industry, the aluminum alloy doors and windows industry has also experienced rapid growth in recent years.

The corner strength of aluminum corner codes is an important performance indicator for the quality of doors and windows. If the corner strength is not sufficient, it will lead to excessive deformation of the diagonal of the window frame during transportation or construction of doors and windows. This can lead to quality accidents.

At present, most of the products on the market use ordinary corner assembly technology and traditional movable corner codes. This simple mechanical fixation is a rigid connection. During the production and installation process of doors and windows, screws may become loose and damaged due to handling, transportation, installation construction, and various forces during use.

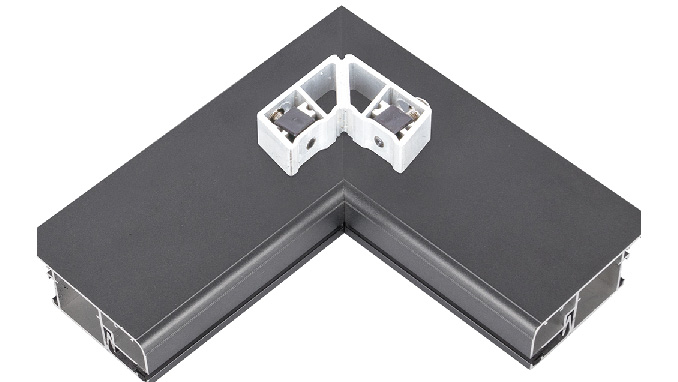

In the development of the door and window industry, adhesive corner codes have emerged, which apply anti-seepage adhesive on the profile section, insert corner codes, assemble corners, and inject two-component adhesive into the injection port. Glue injection can truly maintain a layer of adhesive between the corner bracket and the inner wall of the profile, forming an adhesive tape between the profile and the corner bracket, tightly connecting the corner bracket and the profile together.

During the process of corner assembly, a professional two-component glue gun is used for glue injection. The two-component glue gun can meet the mixing needs of various types of glue, avoiding problems such as incorrect mixing ratios, uneven mixing, and high waste during use, greatly improving the efficiency and quality of glue application.