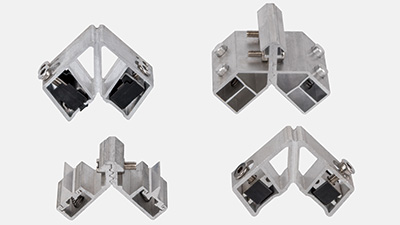

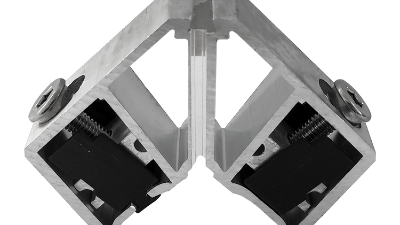

Corner code is one of the hardware accessories that is easily underestimated. The main reason for this is that its self installation is too concealed and often difficult to detect.

In daily life, corner codes are constantly present. From the desktop fixation of office desks and chairs to the assembly and splicing of aluminum alloy doors and windows, the absence of corner brackets in daily life can bring a lot of trouble.

Using the raw materials of corner codes as the classification standard, common corner codes often include aluminum alloy corner codes and plastic corner codes. From the perspective of the performance of the corner code itself, the corner code performance of aluminum alloy is significantly better than that of plastic corner code. Of course, there are many classification standards for corner codes, such as classifying them from the perspective of installation objects.

Compared to relatively low-cost plastic corner codes, aluminum corner codes inherit the characteristics of aluminum alloy profiles. Having the characteristics of rust and corrosion resistance, some high-end furniture and aluminum alloy doors and windows often choose aluminum alloy corner brackets instead of durable plastic corner brackets during assembly and installation.

Some of the top aluminum corner codes in the industry often focus on the processing efficiency of the corner codes themselves when purchasing corner codes. With the improvement of equipment automation level, this indirectly reduces the burden of labor costs on enterprises themselves.