Aluminum alloy windows have poor waterproof performance, with 90% of it manifested in the imperfect manufacturing process of window corner joints. Injecting adhesive corner codes can solve this problem. High pressure filling of imported sealed corner joints enhances the splicing strength between window corners by 6 times compared to general corner code splicing! Strengthen the airtightness of aluminum alloy windows and improve their waterproof performance!

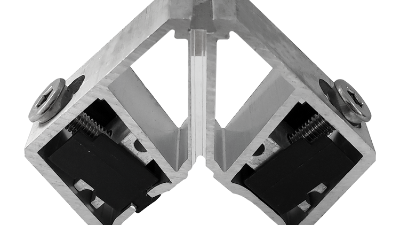

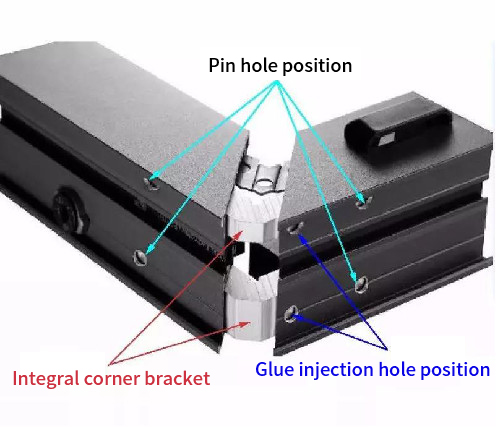

The adhesive corner code is L-shaped and includes two support arms. A continuous guide groove is set along a 45 ° diagonal line at the joint of the two support arms. From the positioning groove to the top corner, the outer surface of each support arm has a taper, and the tapered outer surface forms the adhesive surface. The formed taper creates a gap between the adhesive surface and the reference surface such as a horizontal or vertical plane. Two support arms are inserted into the cavities of the horizontal and vertical frames respectively. At this time, a gap is formed between the bonding surface of each support arm and the cavity wall of the frame material. Then, glue is injected into the top corner of the guide groove, and the filled glue will flow into the gap. The joint of the horizontal and vertical frames and the cavity wall are respectively bonded to the guide groove and bonding surface of the glue injection corner code to complete the corner assembly.

The dual component injection process of adhesive corner code in the guide groove ensures the strength requirements of the corners and guarantees that there is no deformation or displacement of the door and window products after transportation and installation.

The corner adhesive used for door and window corner coding is a product specifically designed to enhance the strength of door and window corners and improve sealing. Its performance characteristics mainly include the following:

1. After curing, it has high hardness, strong strength, good toughness, low elasticity, and excellent waterproof performance. It can make the bonding between the corner bracket and the profile cavity wall a tough connection, thereby repairing and reducing various deformations and cracking conditions, effectively solving the leakage problem at the corners of doors and windows.

2. After curing, the bonding strength is high, and during the curing process, it slightly foams and expands, forming an elastic pad between metal connections to weaken the transmission of various forces and serve as a shock absorber and cushion.

3. Strong weather resistance, able to withstand temperature changes ranging from -40 ℃ to 80 ℃.