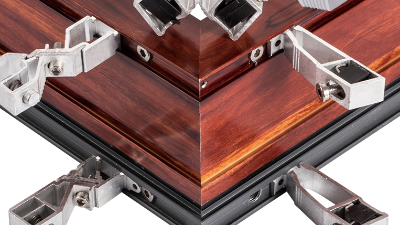

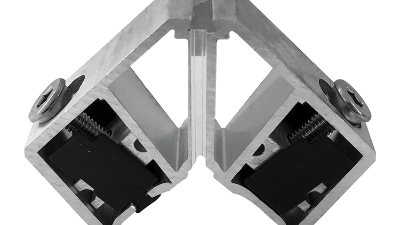

Activity corner code splicing, collision angle glue corner code splicing, integrated glue corner code splicing

As is well known, for aluminum alloy doors and windows, the strength and sealing of the corners are very important, determining the splicing strength and waterproof degree of the doors and windows, directly related to the stability of the doors and windows and the later service life. Aluminum alloy doors and windows 45 ° angle splicing method

Activity corner code technology

It is a common process in daily life, which refers to connecting doors and windows with aluminum materials through spring buckles and tightening them with screws. Compared with the glue injection process, the advantage of using the movable corner code process is that it can be disassembled and assembled on site at any time, which is more flexible and cost-effective. Therefore, most brands are using it, but there are many holes left during processing, making waterproof treatment difficult. Therefore, the selection of materials and the splicing process of the movable corner code are also very particular.

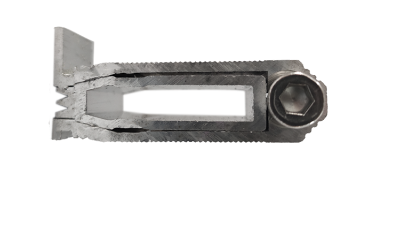

Collision angle injection process

On the basis of the activity corner code, it is a consolidation and extension. Many boasted glue injection processes in the market basically use collision angle glue injection. As the name suggests, it is based on the collision angle process and achieves a stable 45 ° angle through internal and external injection of glue. However, there is no track setting for corner injection, and the amount and density of injection depend on the mood of the installation technician or the drying time during the injection period. There are problems such as deformation, distortion of profiles, and fogging of glass, and sometimes the impact angle injection molding process is even more common than the movable corner code.