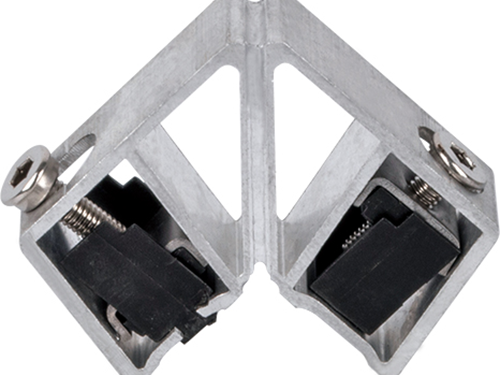

In the design of the flow channel for adhesive corner code injection

The flow channels of the injection angle code have exclusive scientific designs, with dedicated channels at the 45 ° joint. The diameter of the channels is usually designed to be close to the diameter of the injection hole.

Ensure sufficient and fast injection of glue, without wasting corner glue; However, the injection of adhesive for collision angles is currently mostly an improvement of traditional collision angle codes on the market, without specialized channel design. There are many injection chambers and relatively large injection spaces, making it difficult to ensure sufficient injection in practical operations. Insufficient injection can greatly reduce water and air tightness.

Installation and transportation

For situations where the volume of doors and windows is large, the floor is high, and the transportation aisle is narrow, etc., it is inconvenient to transport:

Corner code gluing can be done without gluing after factory assembly, and can be adjusted and glued during installation, taking into account installation and transportation considerations; However, the injection of glue into the collision angle is caused by the deformation of the profile, and even if the glue is not injected after assembly, it cannot be disassembled, which poses hidden dangers such as inconvenient installation and transportation;

From the above analysis, we can easily understand that the glue injection corner code process makes the corner code more compatible with the internal cavity of the profile, resulting in higher rigidity of doors and windows. At the same time, the glue injection is more thorough and uniform, and the profile has better water and air tightness. It can also be glued on the construction site for flexible and convenient installation, further reducing the cost of losses during transportation.